This is the "large machine" area of the shop. Even though it looks a little crowded, I can easily move wood from one machine to another without moving things around. The white machine in the foreground is a Performax thickness sander, one of the most often-used tools in the shop.

This is the "large machine" area of the shop. Even though it looks a little crowded, I can easily move wood from one machine to another without moving things around. The white machine in the foreground is a Performax thickness sander, one of the most often-used tools in the shop.

This is the reverse of the last picture-looking from the large machine area toward the smaller machines. The drawer underneath the table saw collects most of the dust. As you can see, I save a little shop space by tucking my planer beneath the table saw.

This is the reverse of the last picture-looking from the large machine area toward the smaller machines. The drawer underneath the table saw collects most of the dust. As you can see, I save a little shop space by tucking my planer beneath the table saw.

Here is a "wood's-eye" view of the planer. The planer doesn't get as much use now that I have the Performax.

This is a ShopSmith multi-function tool. I use it as a lathe, disk sander, table saw, horizontal boring machine, drill press (when my small one isn't big enough), and for buffing out finishes. My father has been using his ShopSmith for well over forty years and both he and the

This is a ShopSmith multi-function tool. I use it as a lathe, disk sander, table saw, horizontal boring machine, drill press (when my small one isn't big enough), and for buffing out finishes. My father has been using his ShopSmith for well over forty years and both he and the

![]() machine are still going strong.

machine are still going strong.

The edge sander (on the right) is now doing most of the work the jointer (on the left) once did.

The radial arm saw is one of the newer tools. It took me about a month to get used to it, but now I wonder how I got by without it. I use it for cutting dadoes, tenons, and crosscuts that are less than 18 inches. The radial arm saw gets a lot of undeserved bad comments from

woodworkers, but I have been very satisfied with what this machine can do.

The radial arm saw is one of the newer tools. It took me about a month to get used to it, but now I wonder how I got by without it. I use it for cutting dadoes, tenons, and crosscuts that are less than 18 inches. The radial arm saw gets a lot of undeserved bad comments from

woodworkers, but I have been very satisfied with what this machine can do.

The Delta 12 inch band saw is a little too small for my shop and I think I would be happier with a Jet 14 inch saw. The benchtop belt sander is primarily used for sharpening pencils and grinding the nicks out of plane irons before I sharpen them by hand. I didn't spend too much on the Ryobi spindle sander and it has performed quite well, although I wish the spindle were a little smaller so it would fit in some tighter spaces.

The Delta 12 inch band saw is a little too small for my shop and I think I would be happier with a Jet 14 inch saw. The benchtop belt sander is primarily used for sharpening pencils and grinding the nicks out of plane irons before I sharpen them by hand. I didn't spend too much on the Ryobi spindle sander and it has performed quite well, although I wish the spindle were a little smaller so it would fit in some tighter spaces.

My ten-inch Delta miter saw does an okay job, but I would be happier with a DeWalt 12 inch saw. The DeWalt biscuit joiner is bolted to the table and I add or remove shims to raise it when necessary. The vacuum cleaner hose on the Porter Cable Quicksand can be connected to

My ten-inch Delta miter saw does an okay job, but I would be happier with a DeWalt 12 inch saw. The DeWalt biscuit joiner is bolted to the table and I add or remove shims to raise it when necessary. The vacuum cleaner hose on the Porter Cable Quicksand can be connected to ![]() the biscuit joiner.

the biscuit joiner.

This small drill press sees a lot of action. Only rarely do I need the capacity of the ShopSmith.

Almost all of these handplanes were junkers that I bought at yard sales or from the internet. One was so bad that my father thought it was a lost cause (no handle or knob, completely encrusted by rust) and now it's a good worker that I use all of the time. (It's on the cabinet on the left, one shelf up with the bottom.) The two long planes in the center are Stanley #8 jointer planes. The workbench was built in the shop, and the vices on each end were sitting unused in my father-in-law's pole barn. I use both vices at once to clamp long boards, and the barely visible vice on the left can also hold boards vertically.

Almost all of these handplanes were junkers that I bought at yard sales or from the internet. One was so bad that my father thought it was a lost cause (no handle or knob, completely encrusted by rust) and now it's a good worker that I use all of the time. (It's on the cabinet on the left, one shelf up with the bottom.) The two long planes in the center are Stanley #8 jointer planes. The workbench was built in the shop, and the vices on each end were sitting unused in my father-in-law's pole barn. I use both vices at once to clamp long boards, and the barely visible vice on the left can also hold boards vertically.

This is my "main" workbench. It has a large tail vice and two rows for bench dogs. It is not bolted to the floor and I often slide it around. Because it is the same height as the other bench I can suspend large projects between them, almost like a pair of overgrown sawhorses.

This is my "main" workbench. It has a large tail vice and two rows for bench dogs. It is not bolted to the floor and I often slide it around. Because it is the same height as the other bench I can suspend large projects between them, almost like a pair of overgrown sawhorses.

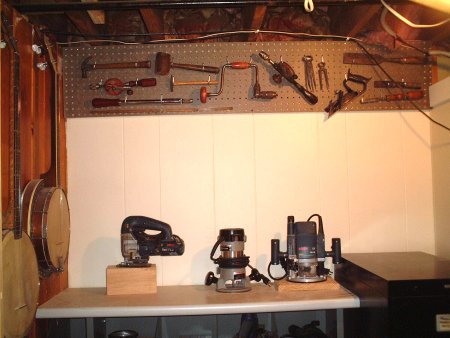

Some of the tools on the pegboard belonged to my father, each of my two grandfathers, and my wife's grandfather. Every now and then I take one out of the display and call it back into action. The banjos, BTW, are also pretty old and are also functional. (The one on the left is an Orpheum plectrum and the one on the right is a Stromberg-Voisonet tenor.)

Some of the tools on the pegboard belonged to my father, each of my two grandfathers, and my wife's grandfather. Every now and then I take one out of the display and call it back into action. The banjos, BTW, are also pretty old and are also functional. (The one on the left is an Orpheum plectrum and the one on the right is a Stromberg-Voisonet tenor.)

This bench is for "fingerboard" work, such as inlaying mother of pearl and hammering frets.

This is the bench where I do the "non-woodworking" projects-soldering wires, fixing garden hoses, or whatever.

This is my "glue-up" area. The row of vices on the front of the bench are for gluing up banjo necks.

This wood storage area is actually in a closet. I also have longer boards tucked away in the joists and sheet goods in a seldom used corner behind the furnace.

My dad built this door for my old studio loft but it seems right at home in the new shop. It keeps noise and dust from drifting up the stairs to the living quarters.

Here a few new additions since I took the above pics for the shop tour.

The biggest change is my new General International table saw. It's a great saw, with plenty of horsepower and a good fence.

I've upgraded to a two-stage dust collector, mostly because emptying my old one made a dust storm in the shop.

This lathe was a gift from my dad. It's rock solid and I've added a new motor, and it will do a great job turning banjo rims.

If you like shop tours, check out Matthias Wandel's website, well worth a visit for a look at his computer controlled box joint jig and home made pipe organ. Click here to get to Matthias's home page.

Return to Top