The Mark V has been in and out of production since 1953, and is currently being manufactured by Shopsmith, Inc. This model has improved over the years, and telling the difference between the various models can be tricky. Headstocks that look identical on the outside can be different on the inside, especially if the owner has upgraded the parts. This particular Mark V is a model 510.

The Model 500 is the most basic Mark V, and although well-designed, early versions lack safety equipment, dust collection, and use a one-bearing quill. Later models are significantly better.

The Model 510 headstock is the same as the newer 500, but it has an improved fence and rail system, a larger table, a crank adjustment for raising and lowering the table, and a few other minor changes. Although it looks very similar, it is a much-improved machine.

The Model 520 is the newest and best, with an even more improved fence and rail system. In all other respects, it is identical to the 510. If you're going to use the Shopsmith as your primary table saw, it might be worth the money to invest in a 520.

The 10 E and 10 ER are the original Shopsmith models. They provided the basic idea for the current Shopsmith. They are well-built machines and many of these fossils are still doing great work. They are characterized by exposed belts and an 8 ľ" table saw blade.

Bob Chambers, one of the founders of Magna Engineering (the original manufacturer of the Shopsmith) is standing next to this chromed out 10er. It wasnít a regular production item, but it sure is cool! (Photo courtesy of Dave Folkerth)

The Mark II (1958-1960) was an odd machine that was a step in the wrong direction. It was NOT built to Shopsmith standards, and was sold exclusively through Montgomery Wards. Avoid this machine.

The Mark II (1958-1960) was an odd machine that was a step in the wrong direction. It was NOT built to Shopsmith standards, and was sold exclusively through Montgomery Wards. Avoid this machine.

I've never actually seen a Mark VII, but I was able to get these pictures from eBay sellers who were nice enough to let me use them on my website. From what I understand, the Mark VII had built-in dust collection, the motor could be run in forward or reverse, and the headstock could be positioned sideways (like a lathe), quill down (like a drill press) or quill up (unlike anything Iíve ever seen). Unfortunately, the speed control was plastic and had a tendency to melt. Production of these machines began in 1960.

Sawsmith 2000

This machine was ahead of its time, and thatís probably why it didnít catch on. It was a 1Ĺ HP enclosed base table saw which could also perform the function of a radial arm saw. The saw blade moved beneath the wood, rather than over it, which made it safer than a typical radial arm saw. This machine was only in production for a short period of time (1985-1987).

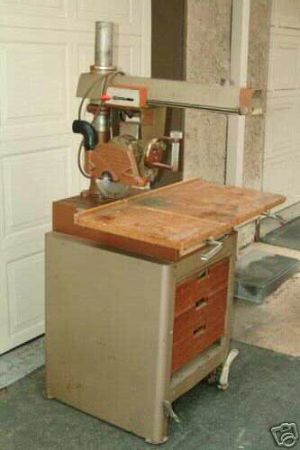

Sawsmith Radial Arm Saw

The Shopsmith radial arm saw is the tool that accidentally created the rebirth of the Shopsmith company. Current Shopsmith CEO John Folkerth purchased a used one, discovered that some necessary parts were no longer available, and through a series of unlikely events ended up resurrecting the Shopsmith Mark V. This machine went out of production in 1965. (Photo courtesy of George Jew.)

Often Overlooked Changes to the Mark V

The Mark V was a good machine, and it has improved over the years. From the gitgo it had some real advantagesóimproved speed changes, the ability to accept a larger table saw blade, and the best performance-to-weight ratio.

The older Mark V machines were, by todayís standards, underpowered. Todayís Mark V has a larger motor and a two bearing quill, but there are also a lot of little changes that often go unnoticed.

Hereís another change that is rarely noticed. The machine screw that holds the Shopsmith in the upright position was updated to accommodate an Allen wrench. It should never be more than finger tight, but if it does get stuck you wonít have to tear it up with vise grips.

An even less noticed and more important change is an improved eccentric bushing. Normally this part would be beneath the belt cover, and you would rotate this part to adjust belt tension. I upgraded to the new style of bushing when I changed the belts and bearing on my old machine, and now tightening the belt is much simpler.

Shopsmith Company Home Page